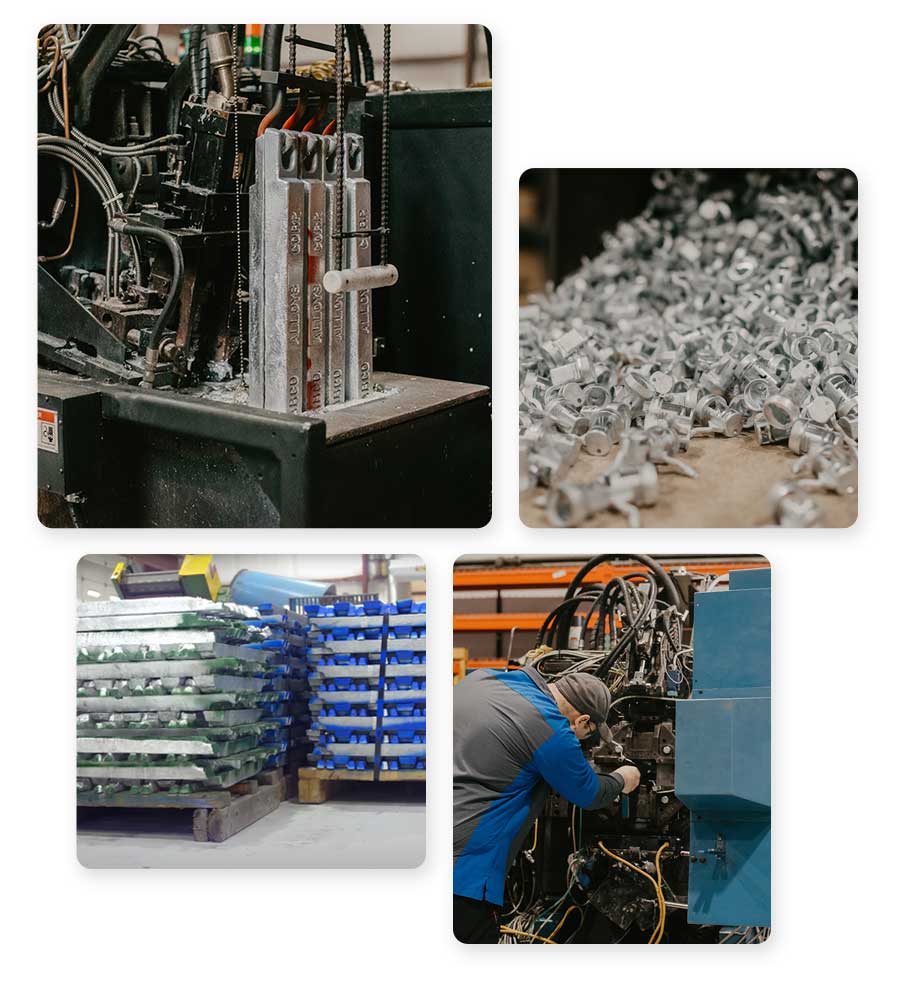

The die casting process is accomplished by injecting molten metal (zinc) into a hardened steel die, also referred to as a mold or tool, under high pressure.

One of the advantages of using zinc is that it can be coated in so many ways. PDC utilizes local vendors to shorten lead times and reduce costs.

Let PDC handle your assembly. We do it right the first time, which means our product will last and function as required. Let us review your project needs.

We are able to provide prototype components that are manufactured to the exact specifications and characteristics of production parts.

You need a company that invests in leading zinc die casting and metal casting technology with a dedicated, experienced team to confidently deliver high-volume production without compromising precision.

The people of Precision Die Cast strive to maintain a clean, productive, and professional environment. Our workmanship and company culture is built on a creative environment that encourages diversity, new ideas, and hard work with the ultimate goal of total customer satisfaction.